When you're diving into the world of oil-free air compressors, especially screw compressors, you'll quickly encounter two main contenders: Water-Injected and Dry Screw (often two-stage dry screw for oil-free applications). Both are engineered to deliver that critical Class 0 oil-free air, but they go about it in fascinatingly different ways.

Understanding these differences is key to selecting the absolute best fit for your specific application, your energy goals, and your operational setup. So, let's get into the nitty-gritty and compare these two impressive technologies!

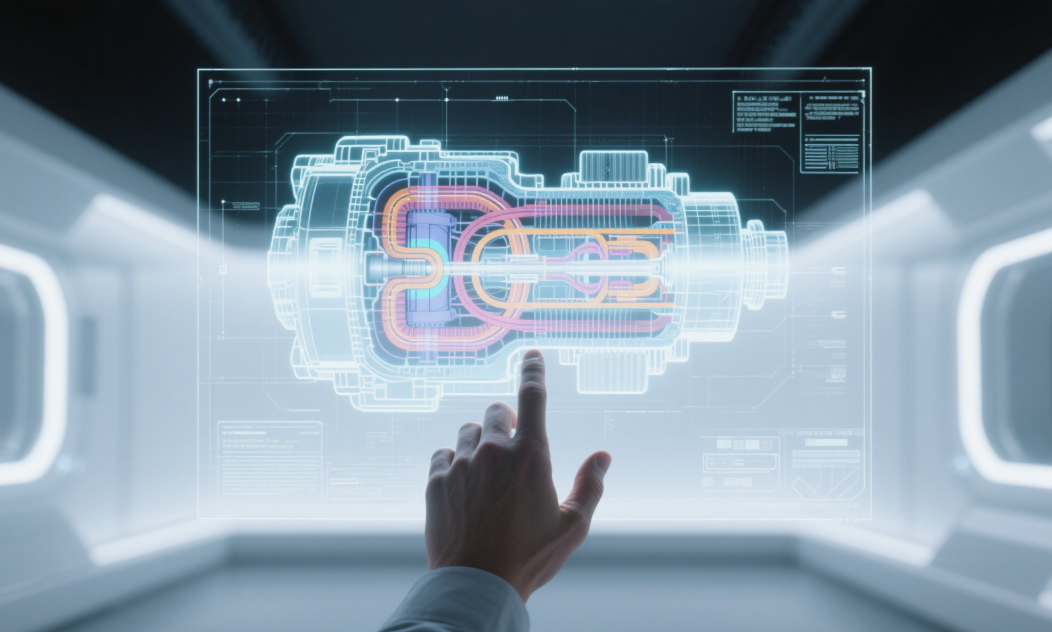

At the heart of any oil-free compressor is the promise of air uncontaminated by lubricating oils from the compression process itself. Both water-injected and dry screw technologies achieve this, but their mechanisms are distinct:

Oil-Free Dry Screw Compressors: These typically use two stages of compression with an intercooler in between for oil-free operation. The screw elements themselves are precision-machined and often feature advanced coatings (like Teflon or Molybdenum disulfide) that allow them to operate without direct liquid lubrication in the compression chamber. The tight tolerances between the rotors and the housing create the seal. They are "dry" because no liquid is intentionally introduced into the screws during compression.

Water-Injected Oil-Free Screw Compressors: As the name suggests, these compressors inject a specific quality of water directly into the compression chamber along with the air. This water serves multiple critical purposes:

Sealing: It fills the gaps between the rotors and between the rotors and the housing, creating an excellent seal.

Cooling: It absorbs the heat of compression directly and very effectively, leading to a much lower operating temperature.

Lubrication (of sorts): While not lubrication in the traditional oil sense, the water film helps the rotors move smoothly.

This fundamental difference in using (or not using) water in the compression chamber leads to a cascade of other performance and operational distinctions.

Let's break down how these two types stack up against each other in crucial areas:

| Feature | Water-Injected Oil-Free Screw | Dry Screw Oil-Free (Typically Two-Stage) |

|---|---|---|

| Compression Process | Near-Isothermal (highly efficient) | Near-Adiabatic per stage (intercooling helps) |

| Operating Temp. | Low (typically < 60°C / 140°F discharge) | Higher (intercooling reduces, but hotter overall) |

| Energy Efficiency | Generally higher due to isothermal compression | Can be very efficient, but often slightly less |

| Discharge Air | Saturated with water vapor (requires drying) | Hot and relatively dry (aftercooling needed) |

| Complexity | Water filtration & treatment system required | Simpler auxiliary systems (no water circuit) |

| Maintenance | Water system upkeep, bearing lubrication (external) | Element coating life, bearing lubrication (external) |

| Noise Levels | Often quieter due to the water-damping effect | Can be slightly noisier |

| Single Stage Max PSI | Can achieve higher pressures in a single stage | Often needs two stages for higher pressures |

(Disclaimer: This is a general comparison. Specific model efficiencies and features can vary. Always consult manufacturer specifications like ours at CMN Compressor.)

One of the standout benefits often touted for water injected screw compressors is their ability to achieve near-isothermal compression. What does this mean? In an ideal isothermal process, the temperature of the gas remains constant during compression. This is the most thermodynamically efficient way to compress a gas.

By injecting water, which absorbs the heat of compression almost instantly, these compressors keep the air temperature very low throughout the process. This results in:

Higher energy efficiency: Less energy is wasted as heat, so more of the input energy goes directly into compressing the air.

Lower discharge temperatures: This can reduce the load on downstream air treatment equipment like aftercoolers and dryers.

Ability to reach higher pressures in a single stage: Less heat means less stress and expansion, allowing for more effective compression in one go.

Dry screw compressors, while highly advanced, operate closer to an adiabatic process (where no heat is exchanged with the surroundings during the screw compression itself ). Heat builds up, which is why oil-free dry screw units for industrial pressures are almost always two-stage designs with an intercooler between the stages to remove heat and improve overall efficiency.

Both types deliver ISO 8573-1 Class 0 oil-free air, which is the critical part. However, the condition of that air differs:

Water-Injected: The air will be saturated with water vapor due to the direct water injection. This means you'll absolutely need an efficient air dryer (refrigerated or desiccant, depending on your dew point requirements) downstream. The condensate, however, is just water (with filtered atmospheric contaminants), making it easier to dispose of.

Dry Screw: The air leaving the compression stages is hot and (after the intercooler and aftercooler) will have a lower relative humidity compared to a water-injected unit before dedicated drying. However, drying is still typically required for most critical applications to reach specific dew points.

So, which one is right for you? It’s rarely a one-size-fits-all answer. Consider a Water-Injected Oil-Free Screw Compressor if:

Maximum energy efficiency is a top priority: The near-isothermal compression often gives them an edge.

Lower operating and discharge temperatures are beneficial for your system or environment.

You have the infrastructure or are willing to install a reliable water treatment system.

You need higher pressures from a single-stage oil-free unit.

Consider an Oil-Free Dry Screw Compressor if:

You prefer simpler auxiliary systems (no internal water treatment circuit).

Your application is extremely sensitive to even the potential for increased humidity directly post-compression (though drying is still key for both).

Specific site conditions or maintenance preferences lean away from water-based systems.

Ultimately, the best choice depends on a thorough analysis of your specific air demand, purity requirements, energy costs, site conditions, and maintenance capabilities.

We at CMN Compressor are always here to help you navigate these options. Both water-injected and dry screw oil-free technologies are fantastic, and we can help you determine the optimal solution to power your operations with clean, reliable air. Don't hesitate to reach out!