1 | Water lubricated oil free | Dry oil free |

2 | Entire machine has no oil | Compression chamber has no oil, rely on sealing |

3 | One stage compression, structure is simple, system is reliable | Two stage compression, complicated structure leads to high failure rate |

4 | Low energy consumption(saving 8~15%) | High energy consumption (Mechanical loss and leakage) |

5 | Low maintenance cost(1/3 of dry oil free) | High maintenance cost(increase every year) |

6 | Low noise | High noise |

7 | Low vibration | High vibration |

8 | The air end rotation speed is as low as 2950r/min | The air end rotation speed is as high as 18000r/min |

9 | Operating temperature is 30℃ | Operating temperature is 200℃ |

Shortcut | If room temperature is lower than 0℃, water needs to be drained manually, otherwise there is a risk that the water and gas barrels may freeze. | If it is shut down for a long time, it needs to be turned on frequently to drive away the tide. If there is a power outage, air end needs to be turned manually, otherwise it has the risk of the air end cracking. |

(1)Structure comparison

Item | Water lubricated oil free | Dry oil free |

Bearing quantity | 7 | 14 |

Speed increasing gear | Motor and air end are directly connected with rotation speed 3000r/m, no speeding increasing gears | With speeding increasing gears, rotation speed is over 18000r/m |

Synchronized gear | N/A | The synchronization gear is used to ensure that the male and female rotor gears are slightly worn and the rotor will be damaged |

Sealing system | 2 groups | 8 groups |

Compression stage | One stage compression | Two stages compression |

Efficiency | High efficiency, minimum efficiency can reach 7.5KW | Low efficiency, minimum efficiency 37kW |

(2)Compressed air solution quality comparison

Item | Water lubricated oil free | Dry oil free |

Impurities | In addition to the filter at the air inlet, pure water washes away impurities in the air, leaving the air almost free of impurities. | Only adopts the inlet air filter, and the peeling off of the screw rotor coating will mix with the compressed air |

Oil | Absolutely oil free | Semi-oil-free; there is no oil in the compression chamber, but there is oil in the gear box. The air and oil are separated by the seal. If the seal is damaged, the compressed air will be polluted. |

Exhaust Temperature | Lower than 50 ℃ | Higher than 180℃ |

Corrosive gas | Pure water neutralizes corrosive gases in the air, and some harmful gases have been dissolved in the water | Inhaled corrosive gases cannot be processed |

Moisture | The outlet temperature is not higher than 50℃, and the atmospheric dew point moisture content at this temperature is 83g/m³ | Because the outlet temperature is ober 180°C, it is over 90°C even after cooling. The atmospheric dew point moisture content at this temperature is 230 g/m³. |

(3)Operation cost

Item | Water lubricated oil free | Dry oil free |

★Electricity | Low, taking 55kW model as example, 8kW electricity saved per hour | High |

★Maintenance consumable | Water filter, air filter | Lubricating oil, oil filters, seals, air filters, rotor coatings |

★Maintenance cost | Low. Taking 30kw as an example, the annual maintenance cost is no more than 3,000 yuan. | High, taking 37KW as an example, the annual maintenance cost is about 10,000 yuan, and will increase year by year. After three years, the rotor coating maintenance cost is over 50,000 yuan. |

★Oil free safety | Because there is no lubricating oil in the air end, it is absolutely safe. | Replacement of the air end bearings, improper installation, or overtime maintenance may cause oil contamination of the compressed air. |

Below pictures show an oil leakage phenomenon of a dry oil free air compressor.

Below pictures show a oil leakage from oil cooling system of a dry oil free air compressor

Maintenance of a dry oil free air compressor is complicated:

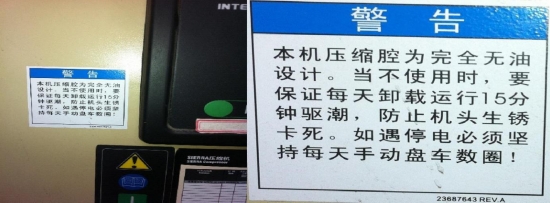

When the machine is not in use, compressor must be unloaded and run for 15 minutes every day to drive away moisture to prevent the air end from getting rusty. In the event of a power outage, must insist on manual turning the rotors for several turns every day. The following pictures are the maintenance instructions of an international brand:

Below pictures shows dry oil free air compressor can not operate due to high temperature warning:

The exhaust temperature of dry-type oil-free machines is as high as 180°C, and the speed of the gearbox of dry-type oil-free machines is as high as 18,000 rpm. That means the bearings, screws, body, and sealing materials have to withstand high temperatures, so they are easily damage. If there is any problem of each part, high temperature will be generated, causing fires, explosions and other accidents.