Hey everyone, it's your friendly team here from CMN Compressor! We talk a lot about compressors, and a question that pops up pretty frequently is about a very specific type: the CO2 compressor. Carbon dioxide is a unique gas, and compressing it has some fascinating applications and, of course, its own set of engineering principles. So, grab a coffee, and let's explore how these vital machines actually get the job done!

At its heart, any gas compressor, including a CO2 compressor, works by reducing the volume of a gas, which in turn increases its pressure and temperature. Think of it like squeezing a sponge – less space, more density!

But why CO2 specifically? Well, compressed CO2 is incredibly versatile. It's used in everything from carbonating your favorite fizzy drinks and food preservation to industrial processes like Enhanced Oil Recovery (EOR), refrigeration systems (it's a great natural refrigerant!), and even in emerging Carbon Capture, Utilization, and Storage (CCUS) technologies.

The "trick" with CO2 is that its properties change quite dramatically with pressure and temperature. It can exist as a gas, a liquid, a solid (dry ice!), or even a supercritical fluid – a fascinating state where it has properties of both a liquid and a gas. Our CO2 compressors are designed to handle these transitions efficiently and safely. This is precisely where the expertise of a specialized CO₂ compressor manufacturer becomes critical. At CMN Compressor, our deep understanding of CO2's thermodynamics informs every design choice, from material selection to system controls, ensuring these transitions are managed with precision.

You might be surprised at just how many industries rely on precisely compressed CO2. At its core, the CO2 compressor's working principle involves taking CO2 gas through multiple stages to increase its pressure and density dramatically. CMN Compressor has perfected this process to transform the gas into a liquid or supercritical fluid, which is the key to its utility in so many different fields. For large-scale operations requiring consistent flow, utilizing a specialized CO2 screw compressor is often the most reliable method to maintain these high-pressure states. We've touched on it briefly, but let's look a little closer at some common applications where our CO2 compressors are real game-changers:

Food and Beverage: This is a big one! From adding fizz to your sodas and beers (carbonation) to modifying atmospheres for packaged foods to extend shelf life, CO2 is indispensable. The pressure and purity requirements here are very specific.

Industrial Cleaning: Supercritical CO2 is an amazing solvent! It can be used for dry cleaning delicate materials or precision cleaning of electronics because it leaves no residue.

Refrigeration: CO2 (R744) is making a huge comeback as an environmentally friendly refrigerant, especially in commercial and industrial systems. It has excellent thermodynamic properties, but it requires compressors designed for its higher operating pressures.

Enhanced Oil Recovery (EOR): Injecting CO2 into oil wells can help extract more oil that's otherwise hard to reach. This requires large volumes of CO2 compressed to very high pressures.

Carbon Capture, Utilization, and Storage (CCUS): This is a rapidly growing field. CO2 is captured from industrial sources, compressed, and then either utilized in other processes or stored underground to mitigate climate change. Our robust compressors are vital for this.

Welding: CO2 is often used as a shielding gas in certain welding processes to protect the weld from atmospheric contamination.

Each of these applications has unique demands for pressure, flow rate, and CO2 purity, which is why having a reliable and well-designed CO2 compressor is so critical. The CO2 screw compressor engineered by CMN is specifically built to bridge the gap between high-volume output and precision pressure control, delivering unmatched reliability for modern production lines.

While there are different types of CO2 compressors (like reciprocating, screw, or centrifugal), let's use a common type, the reciprocating piston compressor, to illustrate the general process for CO2. It's a bit like the engine in your car:

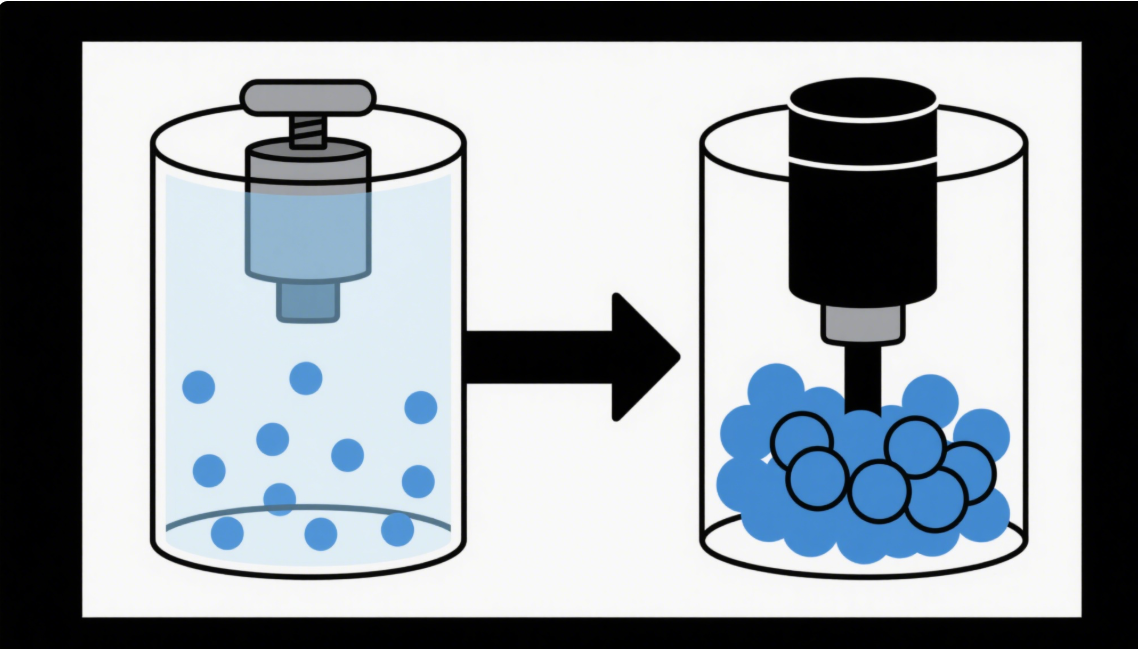

Intake Stroke: A piston moves downwards (or outwards) within a cylinder, creating a vacuum. This draws CO2 gas into the cylinder through an inlet valve.

Compression Stroke: The piston then moves upwards (or inwards), reducing the volume available to the CO2 gas. This is where the magic happens – the gas molecules are squeezed closer together, increasing the pressure and, as a byproduct, the temperature.

Discharge Stroke: Once the CO2 reaches the desired pressure, an outlet valve opens, and the compressed CO2 is pushed out of the cylinder and into a storage tank or directly to its application.

For CO2, especially when aiming for high pressures, this process is often done in multiple stages. Why?

Temperature Control: Compressing gas generates heat. Too much heat can be inefficient and potentially damaging. Multi-stage compression allows for intercooling between stages, where the partially compressed, hot CO2 is cooled down before entering the next compression stage. This improves efficiency and safety.

Manageable Pressure Ratios: Each stage handles a smaller pressure increase, which is easier on the equipment and more efficient.

This multi-stage approach in a CO2 compressor is crucial for handling the gas effectively, especially if we're aiming for conditions where it might become liquid or supercritical.

Compressing CO2 isn't quite the same as compressing air. There are specific challenges and considerations that we at CMN Compressor take very seriously in our designs:

Material Compatibility: CO2, especially in the presence of moisture, can form carbonic acid, which is corrosive. Therefore, materials used in CO2 compressors (like stainless steel or specially treated components) must be highly resistant to corrosion.

Sealing: CO2 molecules are small, and preventing leaks is paramount, both for efficiency and safety (as CO2 is an asphyxiant in high concentrations). High-quality seals and precision engineering are key.

Pressure and Temperature Handling: CO2 compressors often operate at very high pressures and must manage the resulting temperatures, as discussed with multi-stage compression and intercooling.

Phase Changes: The CO2 compressor design must accommodate potential phase changes of CO2 within the system, ensuring smooth operation whether it's a gas, liquid, or supercritical fluid.

Our CO2 compressor range is built with these considerations at the forefront, ensuring reliability, efficiency, and safety for a wide array of applications. By integrating advanced rotor profiles and precision cooling, each CO2 screw compressor we produce delivers unmatched volumetric efficiency for high-pressure carbon dioxide processing.

CO2 compressors are specialized pieces of engineering designed to efficiently and safely increase the pressure of carbon dioxide gas. By employing principles like staged compression and intercooling, and by using materials and designs suited to CO2's unique properties, these CO2 gas compressor machines play a crucial role in numerous industries.

From making your sodas bubbly to helping our planet through carbon capture, the humble CO2 compressor is a real workhorse!

If you have more questions about CO2 compression or need a solution for your specific application, don't hesitate to reach out to us at CMN Compressor. We're always happy to chat!