Hey everyone, from the team at CMN Compressor, we get a lot of great questions about compressors, and one that pops up, surprisingly often, is this: "Can I just use my regular air compressor to compress CO₂?" It's a fair question – they're both gases, right? And compressors, well, they compress!

But, as you might guess, it's not quite that simple. While it might seem possible in theory, using a standard air compressor for CO2 is generally not recommended and can even be dangerous. Let's dive into why.

Air and carbon dioxide (CO2) are very different beasts when it comes to their chemical properties and how they behave under pressure. These differences are crucial when designing a compressor.

1. Corrosion Concerns (The Big One!):

Degradation of internal components.

Premature failure of the compressor.

Contamination of the CO₂.

Air: Standard air compressors are often built with materials like cast iron or aluminum, which hold up fine against regular atmospheric air (mostly nitrogen and oxygen).

CO2: When CO₂ comes into contact with moisture (which is almost always present, even in small amounts), it forms carbonic acid (H₂CO₃). This acid is corrosive to many common metals used in standard air compressors. Over time, this can lead to degradation of internal components, premature failure of the compressor, and contamination of the CO₂.

2. Moisture Content & Dew Point:

Air compressors often have dryers to remove bulk water, but they might not achieve the very low dew points required for some CO₂ applications (like beverage-grade CO₂).

Excess moisture in CO₂ compression is a double whammy: it exacerbates corrosion and can cause operational problems like ice formation if the CO₂ is cooled to very low temperatures.

3. Material Compatibility Beyond Corrosion:

Certain seals, gaskets, and lubricants used in industrial air compressors might not be compatible with CO₂. CO₂ can cause some elastomers (rubbers/plastics) to swell, degrade, or become brittle. Lubricants can react with CO₂, affecting their performance and potentially contaminating the gas.

4. Operating Pressures and Temperatures:

CO₂ is often compressed to much higher pressures than air for applications like beverage carbonation, supercritical extraction, or refrigeration. Air compressors are simply not designed to handle these pressures safely or efficiently.

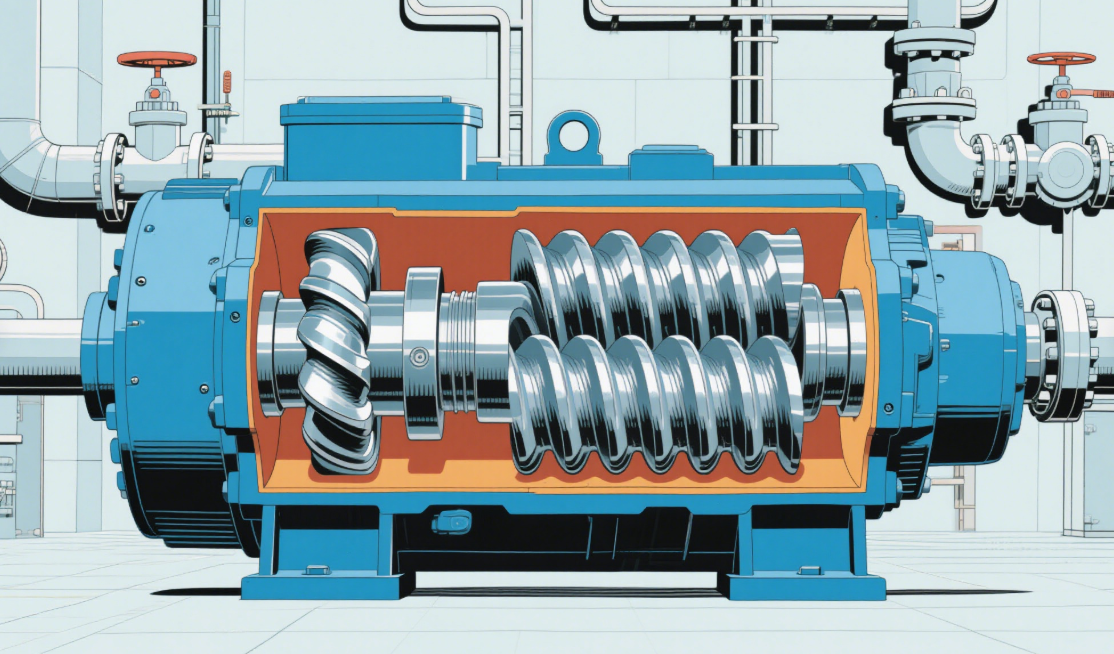

The thermodynamic properties of CO₂ mean it behaves differently during compression compared to air, affecting temperatures and the work required. Dedicated CO₂ compressors are designed with these specific properties in mind, often incorporating multi-stage compression and intercooling.

| Feature | Standard Air Compressor | Dedicated CO₂ Compressor |

|---|---|---|

| Corrosivity | Handles normal air | Resistant to carbonic acid (CO₂ + H₂O) |

| Materials | Standard metals, some plastics | Corrosion-resistant alloys, specific seals |

| Moisture | Standard air dryers | May require very low dew points |

| Pressure Rating | Typically lower to moderate | Often designed for much higher pressures |

| Lubricants | Suited for air | Specific CO₂-compatible lubricants |

(Simple Table: Air Compressor vs. CO2 Compressor Key Differences)

Okay, so we know they're different. But what could happen if you try it?

Rapid Equipment Failure: Corrosion can eat away at critical components, leading to breakdowns.

Contamination of CO₂: Rust particles, degraded seal materials, or incompatible lubricants can contaminate your CO₂ stream. This is a huge issue for food-grade or medical-grade applications.

Safety Hazards: Operating an air compressor beyond its rated pressure for CO₂ is dangerous and can lead to catastrophic failure (think bursting tanks or components). Leaks of CO₂ (which is an asphyxiant in high concentrations) are more likely due to incompatible seals.

Inefficiency: Even if it "works" for a short while, it won't be efficient. You'll likely struggle to reach desired pressures, and energy consumption will be high.

This is where specialized equipment, like our range of CO2 compressors at CMN Compressor, comes in. These units are purpose-built:

Corrosion-Resistant Materials: Utilizing stainless steel, special alloys, and coatings to withstand the carbonic acid.

CO₂-Compatible Seals and Lubricants: Ensuring longevity and preventing contamination.

Designed for CO₂ Properties: Engineered to handle the specific pressures, temperatures, and phase changes CO₂ undergoes during compression.

Safety and Efficiency: Built to operate reliably and safely within the demanding parameters of CO₂ compression.

So, while the idea of using one compressor for everything is tempting, when it comes to CO₂, it's crucial to use a machine specifically designed for the task. It's safer, more reliable, and ultimately more cost-effective in the long run. A purpose-built air compressor co2 provides the necessary corrosion resistance that a standard air compressor CO2 lacks when handling concentrated carbon dioxide.

Got more questions or wondering about the right compressor for your CO₂ application? Get in touch with CMN Compressor – we're always here to help!