Ah, the dreaded sound of silence when you expect the hum of your air compressor, or worse, a strange new noise signaling trouble. We at CMN Compressor know that air compressor failure can bring operations to a grinding halt, leading to frustration and costly downtime. So, what is the most common gremlin in the works?

While it'd be nice to point a finger at one single culprit, the truth is that "most common" can often be a collection of interconnected issues, frequently stemming from a few key areas. Let's dive in and explore the usual suspects that our team sees time and time again. Understanding these can save you a lot of headaches (and money!).

If I had to pick the broadest, most encompassing category for common air compressor failures, it would undoubtedly be insufficient or improper maintenance. It's often the little things, ignored over time, that snowball into big problems. Think of it like never changing the oil in your car – eventually, something major is going to give!

Here’s what falls under this umbrella:

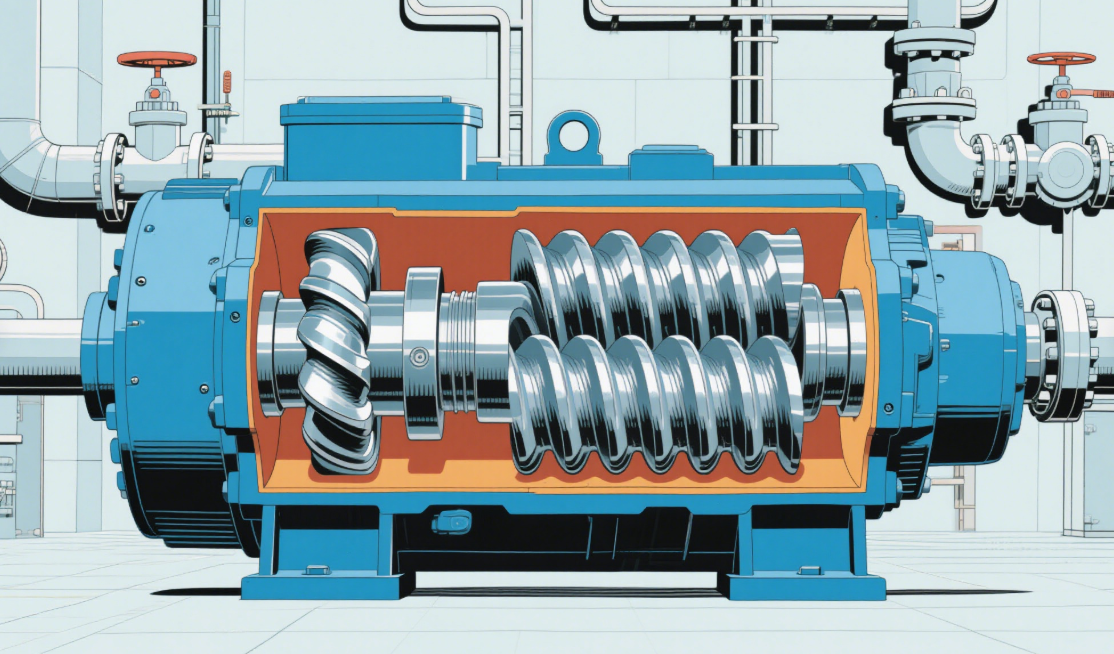

Dirty Filters (Air & Oil): Clogged air intake filters restrict airflow, making the compressor work harder and run hotter. Dirty oil filters can't effectively remove contaminants, leading to premature wear of critical components like bearings and screw elements.

Ignoring Oil Levels & Changes: Too little oil, too much oil, or using the wrong type of oil can lead to overheating, increased friction, and component seizure. Degraded oil loses its lubricating properties.

Skipping Condensate Drain Checks: Most compressors produce condensate (water). If this isn't drained regularly (manually or via an automatic drain), it can lead to corrosion within the tank and air lines, damage to pneumatic tools, and even issues within the compressor itself (like in the oil separator).

Worn Belts & Pulleys: In belt-driven compressors, loose, worn, or misaligned belts can slip, reduce efficiency, generate excess heat, and eventually break, causing an abrupt shutdown.

Regularly scheduled maintenance, as outlined in your compressor's manual, is your first and best line of defense.

An air compressor that's running too hot is a compressor on its way to failure. Overheating can cause a multitude of problems, from lubricant breakdown to component damage and emergency shutdowns.

Common causes of overheating include:

Poor Ventilation: Compressors generate heat. If they're stuck in a cramped, poorly ventilated room, they can't effectively dissipate this heat. They end up drawing in already hot air, creating a vicious cycle.

High Ambient Temperatures: Operating a compressor in an environment that's already very hot puts extra strain on its cooling system.

Clogged Coolers (Oil & Air): Just like a car's radiator, the oil cooler and aftercooler can get clogged with dust and debris, significantly reducing their cooling efficiency.

Low Oil Level or Incorrect Oil: Oil plays a crucial role in cooling many types of compressors.

Electrical issues are another frequent source of compressor meltdowns. These can range from minor annoyances to catastrophic failures. Watch out for:

Motor Failure: Overheating, bearing failure within the motor, winding shorts, or issues with the motor starter can all lead to the prime mover conking out.

Starter/Contactor Problems: These components control the power flow to the motor. Wear and tear, voltage fluctuations, or dust accumulation can cause them to fail.

Incorrect Voltage or Unstable Power Supply: Running a compressor on voltage that's too high or too low, or experiencing frequent power surges/sags, can damage electrical components.

Loose Wiring or Connections: Vibrations can cause electrical connections to loosen over time, leading to overheating at the connection point, intermittent operation, or complete failure.

Sometimes, the compressor itself isn't faulty, but the way it's being used or the system it's connected to is the root cause of its struggles and eventual failure.

Incorrect Sizing: An undersized compressor will run constantly, trying to keep up with demand. This leads to excessive wear, overheating, and a drastically shortened lifespan. Conversely, an oversized compressor that short-cycles frequently can also experience issues with wear on starting components and inefficient operation.

Excessive Air Leaks in the System: If your compressed air distribution system is riddled with leaks, your industrial air compressor has to work much harder and run longer to maintain pressure, accelerating wear and tear. This is a HUGE, often overlooked, energy drain and compressor killer.

High Duty Cycle for the Compressor Type: Not all compressors are designed for 100% continuous duty. Piston compressors, for example, often need rest periods. Running them beyond their designed duty cycle will inevitably lead to premature failure.

While lack of proper maintenance is arguably the umbrella covering the most frequent root causes, it's clear that several factors often play a role. Preventing failure usually involves a holistic approach: diligent maintenance, ensuring a suitable operating environment, addressing electrical integrity, and making sure your compressor and system are correctly matched to your needs.

If you're facing persistent compressor issues or want to set up a robust preventative maintenance plan, our team at CMN Compressor is always here to help. A little prevention goes a long, long way in the world of compressed air!